Be clear, concise, and specific about what you want to achieve, and define simple and straightforward measures to help your employees accomplish your goals.

Leaders at manufacturing and distribution companies tend to have an instinct for problem solving. The culture of the entire industry is predicated on innovation and creating better ways of doing things. And because these same leaders trade in the complex by the very nature of their work, there can be a tendency to overthink solutions to operational challenges, focusing on potential root causes in a way that loses sight of the broader goal.

When we don’t properly align goals with the right supportive actions, we can actually make problems worse. Sometimes the best approach is the simplest.

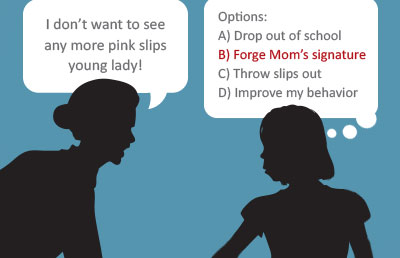

Allegory of the pink slips

The idea of measuring what matters reminds me of an experience my friends had a few years ago. Sitting on a boat with them one summer, I listened as they talked about their daughter, a bright, funny, and very social girl in her early teens. In fact, she was a little too social at school and, as a result, often brought home disciplinary pink slips from her teacher. These pink slips described the problem (too much talking in class) and requested a parent’s signature and reinforcement in correcting the behavior.

The mother, a teacher herself, was irate. She said firmly to her daughter, “I do not want to see any more pink slips.” This admonishment seemed to fix the problem. Her daughter brought home no pink slips during the entire next quarter. When the parents met with the teacher at conferences, however, they were astonished to hear news to the contrary. “Your daughter is doing well,” the teacher said, “except for the pink slips.”

“Pink slips? There weren’t any!”

“Oh, but there were. Four or five for the quarter, actually.”

When the parents arrived home and started the heavy interrogation, they finally got their daughter to admit to falsely signing the pink slips.

Bewildered, the mother asked her daughter why she had done this. The response was matter-of-fact: “You said you didn’t want to see any more pink slips!”

The daughter’s actions underscore an all too familiar problem many manufacturers face today.

It’s normal for management teams to set goals (better behavior) and tie them to the actions they believe will help them achieve those goals (no more pink slips).

When they communicate these goals to their employees, they tend to focus on specific actions (no more pink slips) versus the broader goals they are intended to support (better behavior). But this is limiting and can create problems, making the actions the focus of the workforce. Employees may not understand the ultimate rationale behind their actions and be content to accomplish them by nearly any means. And if management misidentifies the necessary actions to achieve the goal, the allegorical pink slips may indeed go away, but performance doesn’t improve; in fact, it worsens.

Aligning behaviors with goals and setting simple metrics

One of our manufacturing clients faced such an issue. The company was having problems meeting customer deliveries and decided it needed to improve its productivity. The management focused on employee utilization. Management’s thought process was simple: If employees are being utilized on jobs, they are being productive.

It turned out utilization wasn’t the problem. While the company’s utilization numbers continued to rise, so did late deliveries and, worse yet, inventory. The focus on utilization had the opposite effect of what was intended. Instead of concentrating on moving jobs through the system and improving customer service, employees were focused on staying busy. Staying busy meant always needing a job in front of them to work on, regardless of when it would be shipped. This additional inventory created a lot of congestion on the shop floor and made visual management very difficult. Some employees were busy on current orders. Others were building ahead because they had available capacity. This disconnect in workflow meant that almost every job became a “hot” job, and schedule bumping occurred so frequently it became accepted as the norm.

It was soon apparent that looking at utilization didn’t achieve the desired effect of better on-time deliveries. Something had to change.

The company reconsidered its approach (and measurements), instructing employees in all areas of the business to focus on improving customer responsiveness and on-time deliveries.

Every action was evaluated by one basic two-pronged question: “What does the customer need and when does he or she need it?” In less than six months, on-time deliveries improved from 50 percent to over 85 percent. “Sacred cows,” such as building ahead to leverage setups, were challenged in light of their impact on production flexibility and overall capacity. The emphasis shifted to reducing inventory requirements to match customer demand (and the company’s ability to produce).

The moral of the story is: Don’t focus on eliminating the pink slips; focus on improving the behaviors or processes that cause them. Sometimes, big improvements come in relatively simple packages.